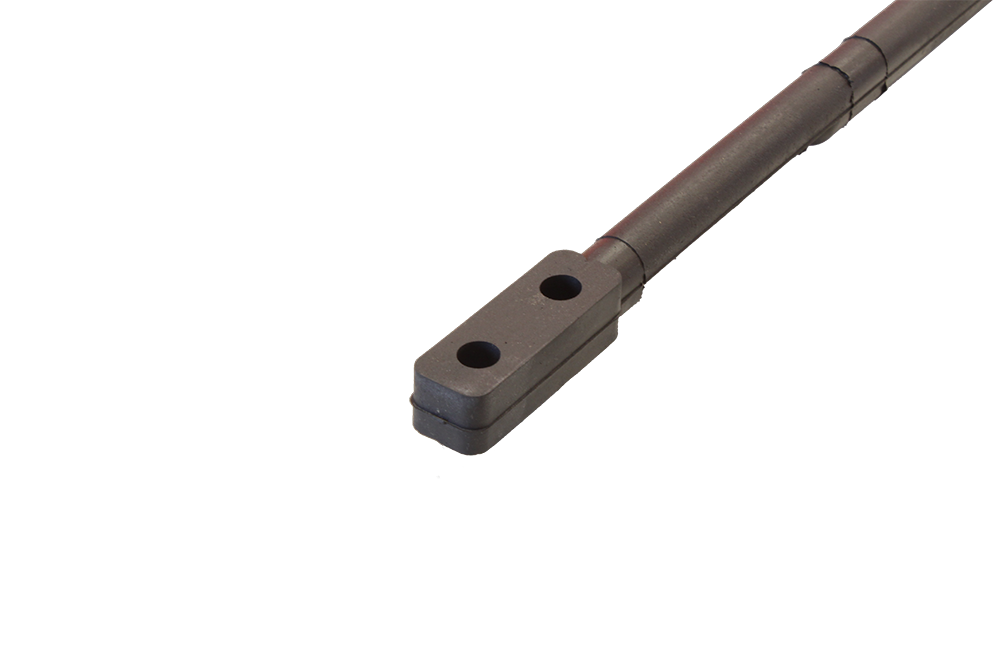

Vulcanized rods

To protect the product from damage, we can vulcanize a soft rubber layer onto the rods. This rubber has a hardness of 30-35° shore. Because the rod is vulcanized over the total length, including the flattenings, this offers optimal protection. With these rods, the centre belt is attached with OGP. Because each rod must be vulcanized in a mold not every width is available.

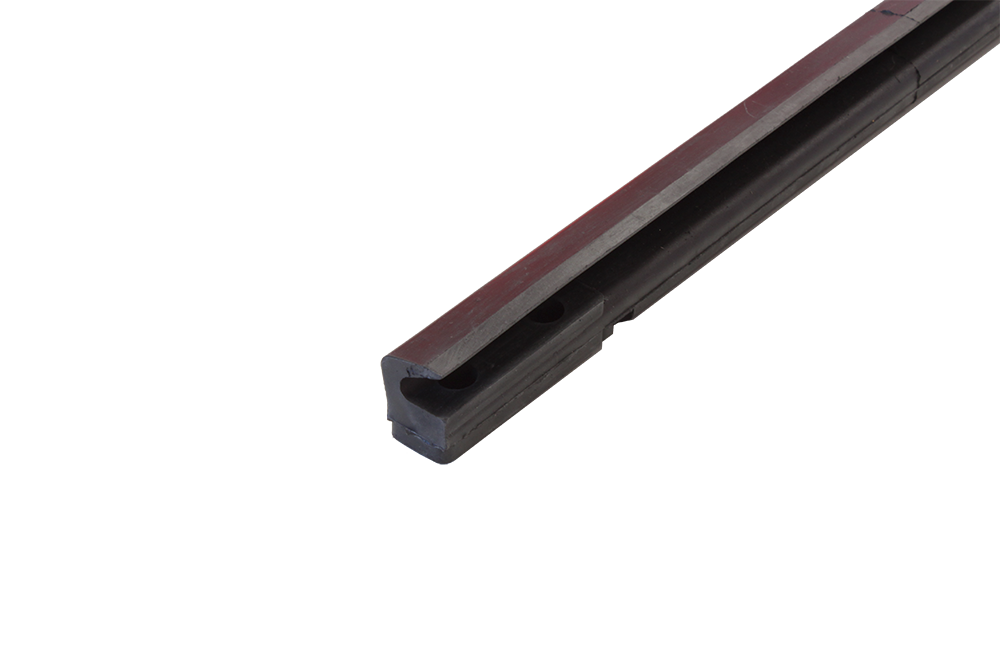

Stokmaat

In determining the correct width of the sieve web, it is important that the rods have the correct “stokmaat”. This is the distance between the two outside rivet holes, C.T.C. When ordering loose rods it is important that you mention the stokmaat as well as the distance between the holes in one end.